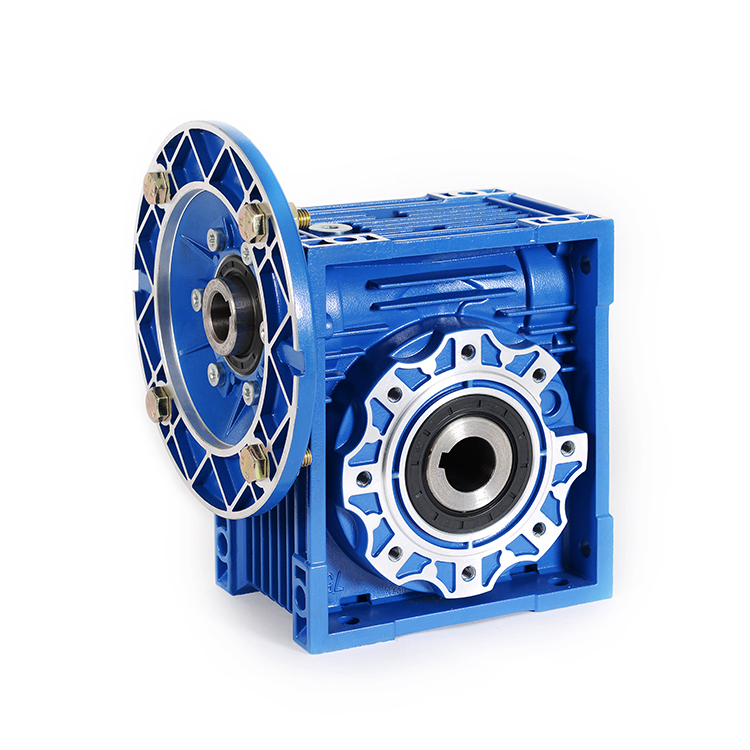

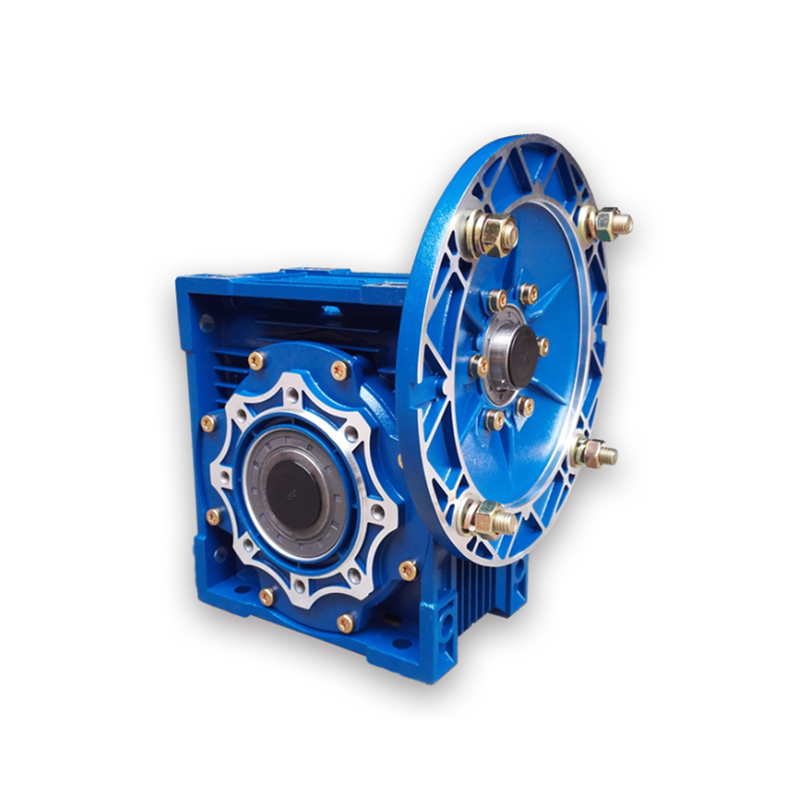

NMRV75 hollow shaft output flange, TA torque arm worm-gear gearbox with IEC standard motor flange

- Place of Origin:

-

Jiangsu, China (Mainland)

- Brand Name:

-

DEVO

- Gearing Arrangement:

-

Worm

- Output Torque:

-

180~230 N.m

- Input Speed:

-

1400 rpm

- Output Speed:

-

14 ~ 186 rpm

- Product name:

-

NMRV75 worm-gear reduction gearbox

- Application:

-

Food Stuff

- Usage:

-

FOOD

- Housing material:

-

Aluminum Alloy

- Gear material:

-

bronze

- Ratio:

-

7.5~100

- Certification:

-

ISO9001

- Quality:

-

High Level

- Warranty:

-

1 Year

- Color:

-

Blue

Packaging & Delivery

- Selling Units:

- Single item

- Single package size:

- 240X250X260 cm

- Single gross weight:

- 20.0 kg

- Package Type:

- wooden case

- Lead Time :

-

Quantity(Piece) 1 – 100 >100 Est. Time(days) 15 To be negotiated

NMRV series worm-gear reduction gearboxs are important transmission machineries. With the features of light-weight, compactibility and flexibility, they well meet the various demands of customers. The series products are applicable for lots of industrial fields, such as cranes, textile industry, metallurgy, conveyor machines, printing and dying, foodstuff industry etc.

Main Features

A gearbox designed using a worm and worm-wheel is considerably smaller than one made from plain spur gears, and has its drive axes at 90° to each other. With a single start worm, for each 360° turn of the worm, the worm-wheel advances only one tooth of the gear wheel. Therefore, regardless of the worm’s size (sensible engineering limits notwithstanding), the gear ratio is the "size of the worm wheel – to – 1". Given a single start worm, a 20 tooth worm wheel reduces the speed by the ratio of 20:1. With spur gears, a gear of 12 teeth must match with a 240 tooth gear to achieve the same 20:1 ratio. Therefore, if the diametrical pitch (DP) of each gear is the same, then, in terms of the physical size of the 240 tooth gear to that of the 20 tooth gear, the worm arrangement is considerably smaller in volume.

Unlike with ordinary gear trains, the direction of transmission (input shaft vs output shaft) is not reversible when using large reduction ratios. This is due to the greater friction involved between the worm and worm-wheel, and is especially prevalent when a single start (one spiral) worm is used. This can be an advantage when it is desired to eliminate any possibility of the output driving the input. If a multistart worm (multiple spirals) is used then the ratio reduces accordingly and the braking effect of a worm and worm-gear may need to be discounted, as the gear may be able to drive the worm.

Worm gear configurations in which the gear cannot drive the worm are called self-locking. Whether a worm and gear is self-locking depends on the lead angle, the pressure angle, and the coefficient of friction.

Dimensions of NMRV75

Characteristics

1 A simple and compact way to achieve a high torque

2 low speed gear ratio, for example, helical gears are normally limited to gear ratios of less than 10:1 while worm-and-

gear sets vary from 10:1 to 500:1

3 Low noise, because of the composition of the worm and gear, NMRV series own a quiet and smooth meshing action

4 They are fit for various mounting positions

5 It is not possible for a worm wheel to drive a worm unless certain conditions are met

Jiangsu Devo Gear Technology Co. Ltd

Our company handles the products of power transmission, associated electricial motors and other power transmission accessories. Our products can be utilized in many fields, with the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in Jiangsu Province, China. Our company owns the ability of manufacturing, processing,

designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models

upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A: We will reply as soon as possible, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food

machinery, packaging equipment, tobacco equipment and so on.