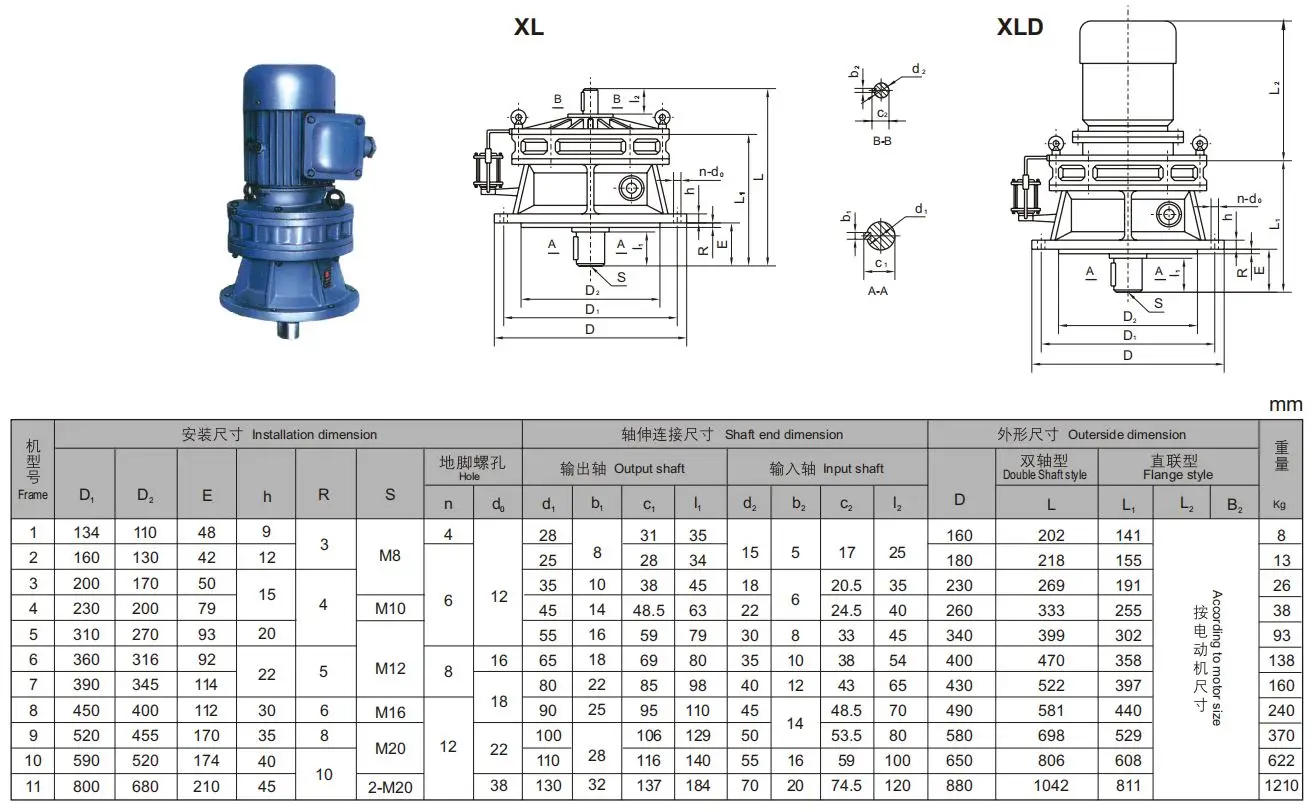

XL XLD unit reduction stage cycloid gearbox gear motor gear reducer with motor

Introduction of Cycloid Reducer

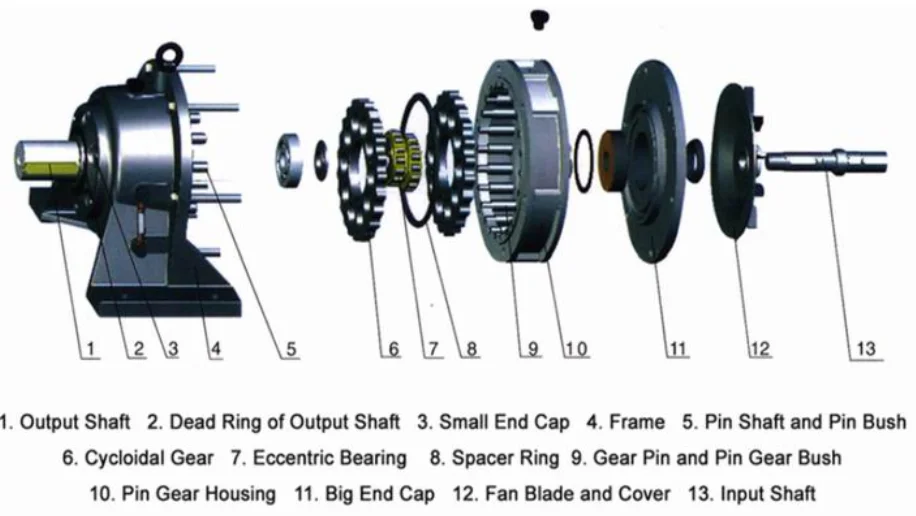

The cycloid gear design has advantages superior to speed reducers using common involute tooth gears. The key to Cycloid Drive matchless performance and reliability is that 67% of the reduction components are in contact at all times, compared to helical gear and planetary gear designs that use only limited tooth contact. Unlike geared designs, the cyclolid reducer’s reduction components operate in compression rather than shear, which results to withstand shock loads exceeding ratings of 500%, provide exceptional performance, reliability and long life in most severe applications.

Applications • Chemical Agitator • Conveyors • Crusher • Automation • water works • Food Machinery • Plastic Machinery • Paper Mills • Printing machinery • Mortal Pump System

Specification

|

High Efficiency

|

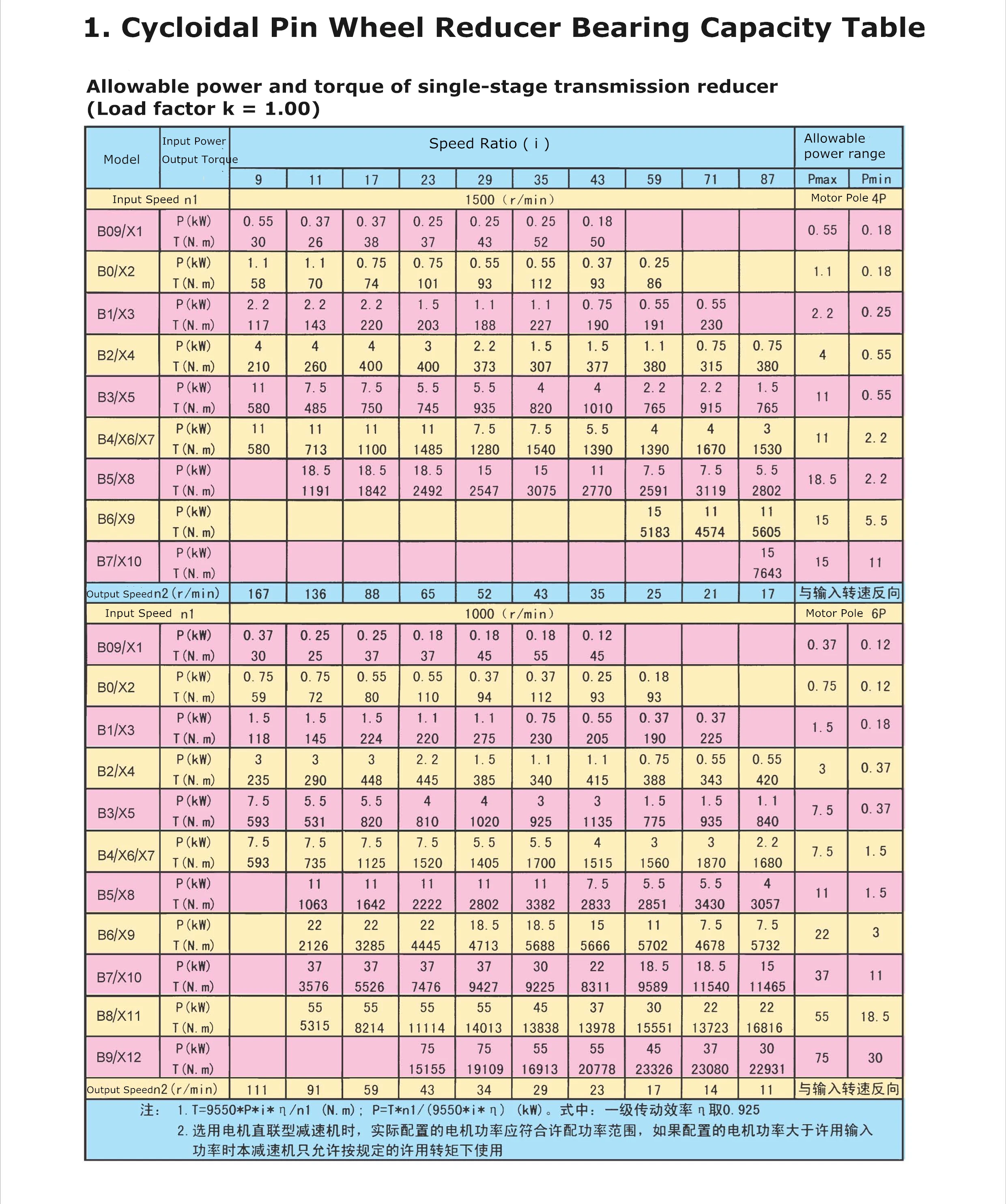

Single stage efficiency approaches 93%, and double stage efficiency approaches 86%.

|

|

Durable and Long Service Life

|

capable of withstanding intermittent shock load up to nearly 350% of its catalog torque rating

|

|

HOUSING

|

Standard gray cast iron provides rigid structural integrity. Optional ductile iron housing is available

|

Write your message here and send it to us